6. GRP Estuary Cruiser

Interior & Deck

The standard interior of small cruisers often has a galley to the left of the entrance, possibly some navigation space to the right and then a seating area forward of that in the main cabin. The forecabin usually has a double berth with toilet under and is screened from the main cabin generally with an athwartship bulkhead. My boat is based on this arrrangement, but does not quiet follow it in total. The boat has a centre cockpit and on such a short craft, this immediately changes things around a little. Most of the pictures below were taken at the end of the season with much of the usual gear strewn about. They are not of sales brochure quality! The descriptions commence from the front and work back:

There is a double ‘V’ berth with a camping toilet below it in this area forward of the daggerboard case. To convert this cabin into the bed a shaped board is dropped into place at seating level, over the walk-in space and two berth cushions

The shaped board used for the berth conversion is also used as a table top when formal seating is required. The seating is already provided for three people by the permanent berth cushions and the table top can be secured at a higher level. Food and utensils can be passed in through the open space above the cooker if needed. The fourth place is provided by a seat inserted across the gangway between the boat side and the daggerboard casing. When not in use the table top stores on the front face of the cockpit inside the main cabin.

Pictures. Top left. ‘V’ berth with single sleeping bag. Shelf over berth.

Right Above. View through to forecabin from main cabin with table and 4th seat (which is level - camera distortion) in place. Daggerboard casing to the right. A mirror on the half-bulkhead gives the illusion of space.

Main Picture. From forecabin looking towards main cabin. Daggerboard is almost central. Open cooker lid is in the space to left. Cabin access to right. On bulkhead behind purple jacket is stored table top. Yellow/blue object on floor is temporarily stored, bagged inflatable.

Main cabin

The boat has the main daggerboard casing slightly offset to starboard where the mast-support bulkhead usually divides off the forecabin. The front of this casing acts as the mast support. To one side of this casing is the access to the forecabin. The casing produces a vertical ‘wall’ parallel to the keel on which to attach additional structures which

The port side of the main cabin has seating for two people, who can also see and converse with people up front through the walk-though access space on their side of the daggerboard. Effectively the whole area is the main cabin and the daggerboard box does not really interfere with that. There are no berths in the main cabin area, so it is mainly used by the two people who will occupy the forecabin berths. They might be called ‘Mum & Dad’. The combined space can also provide seating for four or more people using the two seats to port.

Entrance Access

This main cabin is accessed through a starboard-offset, angled, deck-hatch with steps down the starboard side of the boat. Using this method rather than the traditional central companionway clears more space below. The access deck-hatch also allows the boat to be sealed from inside in the very unlikely event of capsize. Capsize in a trimaran with buoyant floats is improbable in the locations that this estuary cruiser would be used in, because it would require extreme circumstances, plus, the big waves that are needed to capsize trimarans. In heavy wind gusts they behave like a monohull and try to luff up and/or accelerate, but stay upright. Using a sealing deck hatch is a precautionary belt-and-bracers option against other potential problems such as being holed and flooded, because it is a solid permanent closure, not like the flimsy hatch boards often used. Incidentally, cruising catamarans can be wind-capsized, but assuming they are not overloaded and carrying sensible sail, they are very difficult to wave-capsized. It is one of the differences between the multihull craft types. All craft types are vulnerable to extreme wind gusts when stationary, with full sail up, but these are very exceptional circumstances.

At the rear of the main cabin is the engine space and over it is a storage area, below the cockpit. The cockpit ‘floats’ in the middle of the boat, without bulkheads, so it is possible to slide through on the port side into the aft cabin. The cockpit is solidly supported at the rear by the trim board box behind the engine. The aft cabin has two berths and the two people who occupy them may be called ‘The Children’, or ‘The Grandchildren’. Having their own cabin is extremely popular with them, but also with Mum & Dad, as it makes living/relaxing space for all. The aft-cabin starboard berth is large and long as it goes right through to the main cabin. The foot of this berth, in the main cabin, is also used for general storage. It can be

The aft cabin port berth is an extension to the slide-through platform connecting cabins and goes right back to the transom. It has small shelves over and under it. The transom end of the berth is partitioned off from the area to starboard which houses a second camping toilet and a washing area with mirror, bowl and storage for hot and cold water etc. This area is astern of the head of the starboard berth already mentioned. The transom has a sliding opening window. The cabin has fixed windows either side

Aft cabin pictures

Top right. Slide-through access from foot of port berth, towards main cabin.

Left. Toilet/Wash area from port berth. Sliding window in transom.

Right. Starboard berth. Steps up to hatch. Box for engine controls. Hand bilge pump and pipework.

Interior Trim

The boat is foam sandwich and so it is insulated and quiet compared with single-skin plywood craft. It is naturally warm and has no condensation problems, except very infrequently on the fixed toughened-glass windows on either side of the main cabin. The Perspex windows on the aft cabin seem not to be a problem. To avoid any dripping windows the internal sills were machined with a groove running their full length. Any condensation on the windows is caught in this small ‘gutter’ and evaporates later. It is a very successful self-tending system. The whole of the interior is lined. This gives it a really warm, sound-deadened feeling. Trimarans should be kept as light as possible and the weight of this lining might not be justified, but with my commitment to a comfort-cruiser I sometimes break the rules. The interior woodwork is all varnished mahogany. I like its warm colour. The floor is carpeted.

Engine

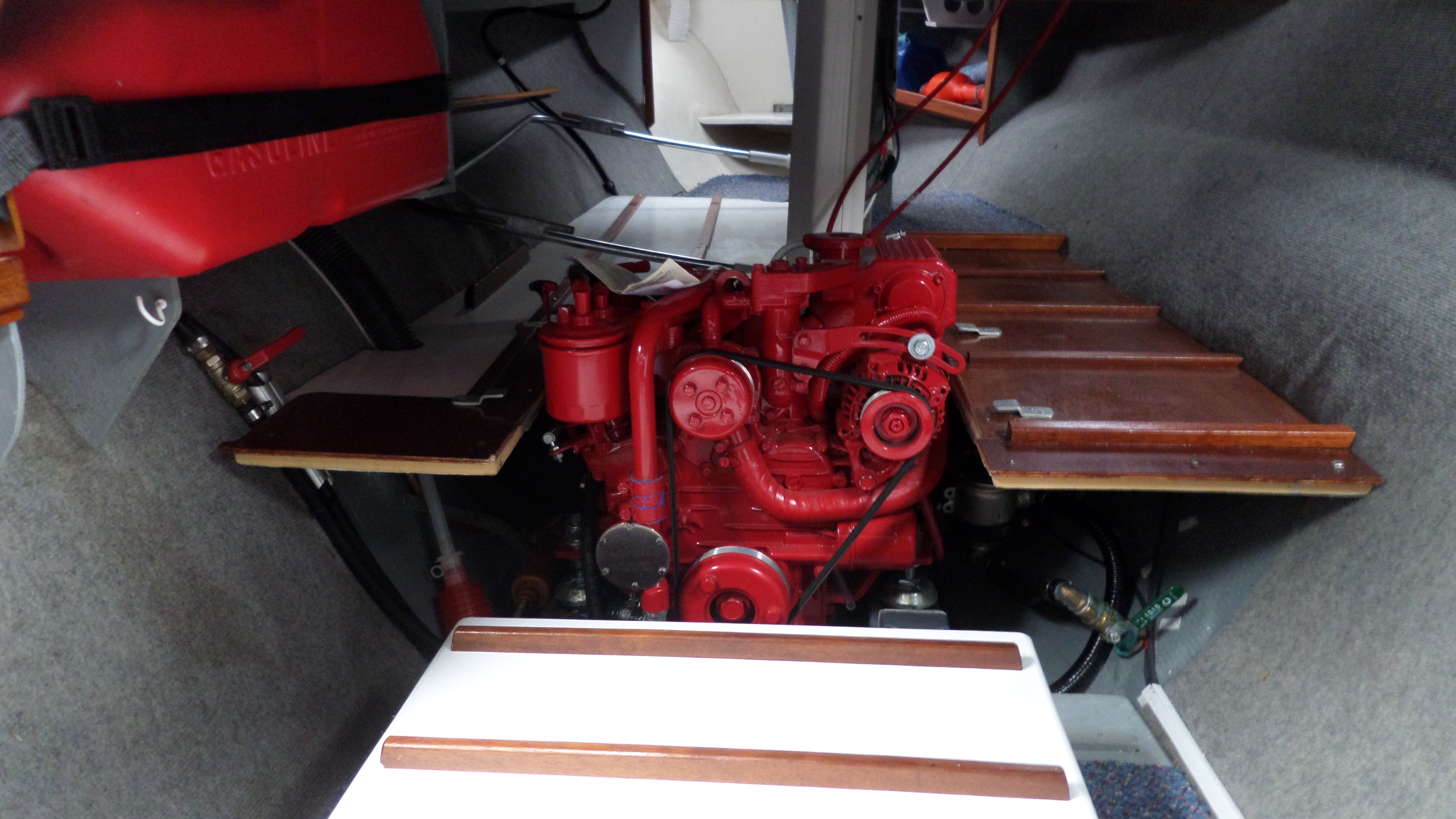

If you read the first section of this account - The Boat, you will be aware of my very unusual wish, for any small-craft trimariners, to have the security of an inboard diesel. Are there any other 25ft trimaran in the world with such a propulsion system? Obviously, I had to keep it as light as possible and originally, I had a BMW D7, driving a folding prop. This very simple little motor was sufficient for moving the boat about on short journeys and for picking up moorings etc. It weighed 64kgs. This was its ‘advertised’ weight. When an engine is fitted, it has many other additional components for its systems, prop, prop shaft, stern gland, engine controls, fuel lines, filters, cooling system, etc. etc. so it will be heavier, but the weight in total might approximate to having an additional person on board. The

After 35 years I changed the engine for a more updated one. The boat now has a Beta 14 twin cylinder instead of the single cylinder D7. The main reason for this was the extra power. The D7 was acceptable when the conditions were not adverse. Trimarans have big windage, but little in the water. Once the wind reached F4 the little engine struggled to push the boat against it. If an adverse tide was added, progress could hardly be made. The River Deben where we sail, has a notorious bar at the mouth where the narrow channel squeezes the tidal flow up to 6 knots at times. Crossing the shallow bar dominates access times and restricts cruising destinations outside the river, so fitting the larger engine has made a great difference to the way the boat can be used. We now have confidence that the bar can be crossed, even when the elements are against us. The penalty was the 97Kgs weight of the replacement engine, together with additional ancillary equipment. The only weight saving that I could find to reduce this 33kgs penalty was in myself. I went on a diet and managed to lose 16ks so the net result was only a 17kgs penalty. It takes dedication to sail a trimaran, but it is a healthy option. The boat uses the same folding-prop, stern gear and single-lever engine control in the cockpit as the previous engine. Two boards cover the engine, with a box over it. This allows rapid access if it should be needed. The air intake is directly linked to the cockpit. A rotating air grill at the front of the engine box allows access to the water-intake valve and the main electric power switch for the engine without opening up the covers. An engine compartment air-extraction pump is switched from the cockpit.

The only underwater, through-hull seacock is for the cooling water intake for the engine. The exhaust outlet is above water. Both toilets are ‘camping’ and retain waste.

Electrics

For many years there was only a single battery, but a second one (further weight) has been fitted as the new engine has an alternator, which the previous engine did not have. The boat also has about 120 watts of solar power from on-deck flexible panels, operating through two controllers. All interior lights are now LED. The depth sounder transducer operates from inside the hull, so there is no hole. Speed is recorded on a hand-held GPS which is more accurate than the old logs, especially the paddle-wheel type which were vulnerable to weed. In coastal cruising, speed through the water is rarely an indication of position. In reasonable wind speeds the boat usually travels at about 4 - 7 knots, but the highest recorded speed is 13.2knots, running in waves, starting to plane, too much sail and rather scary! Navigation lights are battery-powered as they are rarely needed. They attach to the rigging above the floats (see Floats & Beams) to indicate the width of the craft. The anchor light is LED and runs from the domestic battery with a through-deck plug.

On Deck

The Stern deck

Cockpit

It is of interest that in the modern trend of ‘endurance offshore sailing’ in quite small boats made popular by such sailors as Blondie Hasler in Jester or Roger Taylor in Mingming, that one of the first major modifications is to dispense with the cockpit for ocean-going craft. The 22'-6'' Night Heron design by Thomas Firth-Jones mentioned in Floats & Crossbeams had no cockpit and Arthur Piver’s original demountable, Nimble did not have one either.

The cockpit on this boat is deep, with good seating for four. It is self-draining through the trim-board casing towards the rear. The trim board has a short handle projecting through its casing into an open slot on its starboard side. The slot has cut-outs for the handle, allowing the board to be locked in position in three different locations, depending on the depth required. As the bottom of the slot is level with the cockpit floor, any water can drain into the casing and run away. Below. Slot for trimboard control lever. Below. Cockpit general view.

Main deck

Just ahead of the cockpit there are winches. They are very small as they are not needed for sail sheets. To the left is the main halliard winch, with a halliard clutch ahead of it. To its right is the winch for downhauling the yard. There are cleats for line storage. A cleat far left is for the two sheets controlling the forward end of the boom.

Foredeck

A bracket to port is the securing point for the bowsprit, which folds upwards and clips to the forestay. When used, the bowsprit is braced to the front tip of both floats and has an adjustable bobstay secured to the bow. The bowsprit is no longer used (see Section 7. Modifications), but it is still available if required. The bow roller uses a drop-nose pin to secure mooring warps. The very tip of the bow has a teak pad to take the inevitable wear of mooring warps.