GRP Flat-table Boatbuilding 6

Bagging Equipment

The equipment required demonstrates just how low-tech the process can be.

Any vacuum cleaner

An old-fashioned, cylinder type it good. I found one in a junk shop and I still have it (see below). Being small and portable are its best qualities. You will read that the best devices to use are old milking machines and this may be true for commercial production, but vacuum cleaners are quite adequate. When speaking about vacuum bagging there is a misconception that is it the strength of the ‘sucking’ that makes the vacuum bag press down, but this is not the case. Removing the air in the bag allows atmospheric air pressure to act upon the bag and the pressure is considerable. At sea level, one square centimetre has just over one kilogram pressing on it. One square inch has over 14lbs crushing it. We are accustomed to moving around under this enormous load, so we don’t notice it, but we can use it as a cramp over a wide area to hold things flat, which is the secret of the process.

Below Right. Small modern vacuum cleaner

Polythene/pipe connector and my old cylinder cleaner

Cheap adhesive tape. Masking tape is good. Most of it needs to be a bit wider than the usual 20mm so that it can be used without infinite care. 50mm (2ins) is good.

Parcel Tape. This is the brown tape used for packaging parcels. It is shiny on the outside. Its special quality is that polyester resin does not stick to it. To ensure this, it can have a layer of release wax applied to it. It makes pieces of board non-stick.

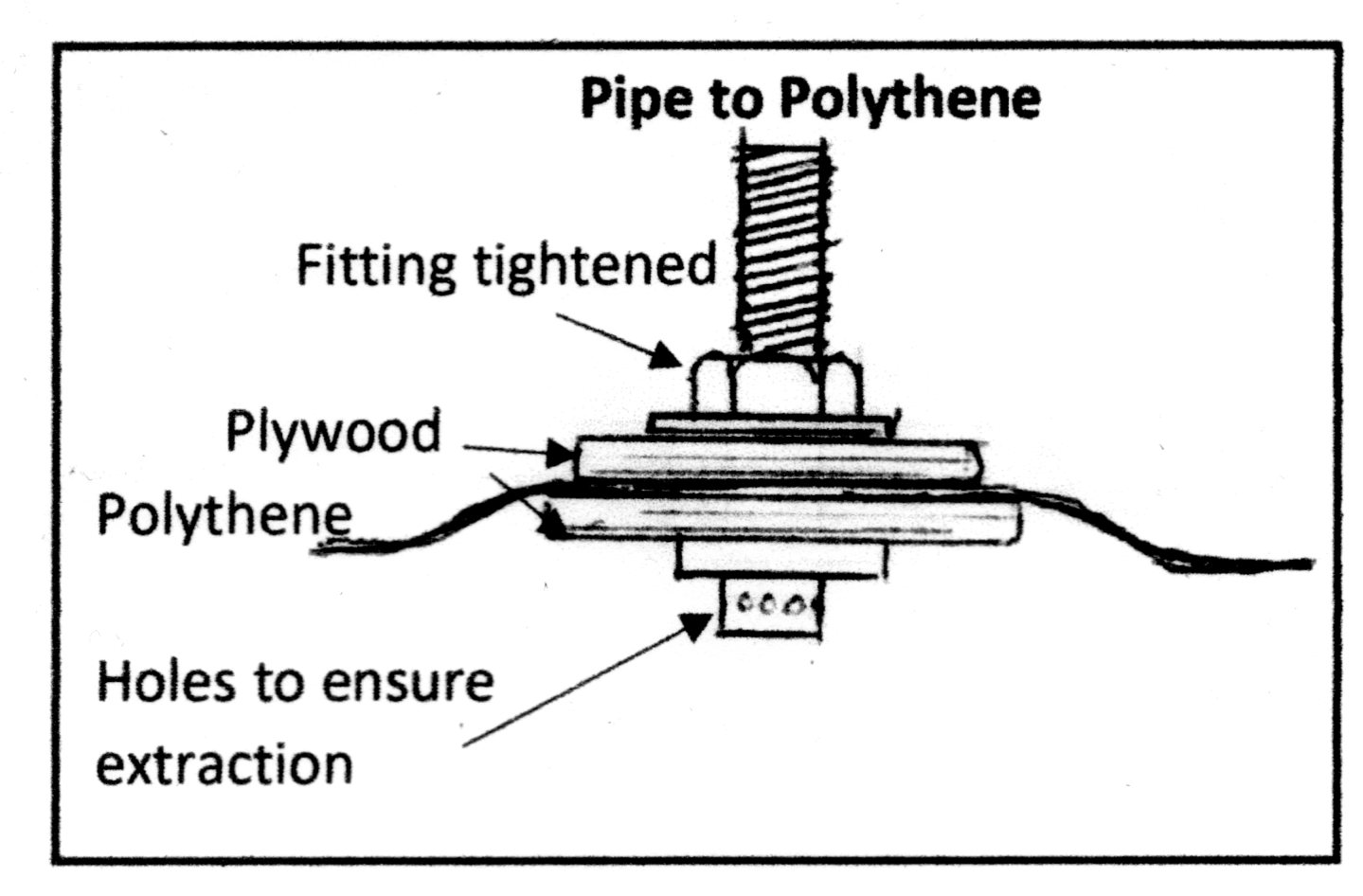

Tube. A short tube made from metal or plastic that is close to the diameter of the vacuum cleaner hose. It could be a domestic pipe fitting for attaching to water tanks, or a marine skin fitting. Its purpose is to be attached through the polythene sheet so that the air can be sucked out.

Tube. A short tube made from metal or plastic that is close to the diameter of the vacuum cleaner hose. It could be a domestic pipe fitting for attaching to water tanks, or a marine skin fitting. Its purpose is to be attached through the polythene sheet so that the air can be sucked out.

Scraps of plywood. Will sandwich the polythene sheet and have a hole drilled through for the attachment of the pipe.

3mm (⅛”) Hardboard or MDF. This is cut into 75mm (3ins) wide strips and used to make recesses for joints.

A number of screws and nails of various sizes.

Vacuum bagging -The concept:

- Place the panel (foam) to be pressured on the table

- Lay the ‘bag’ - Polythene sheet over it

- Tape the polythene down to the table around the edges using the masking tape

- Place the vacuum cleaner onto the tube passing through the sheet

- Switch on!

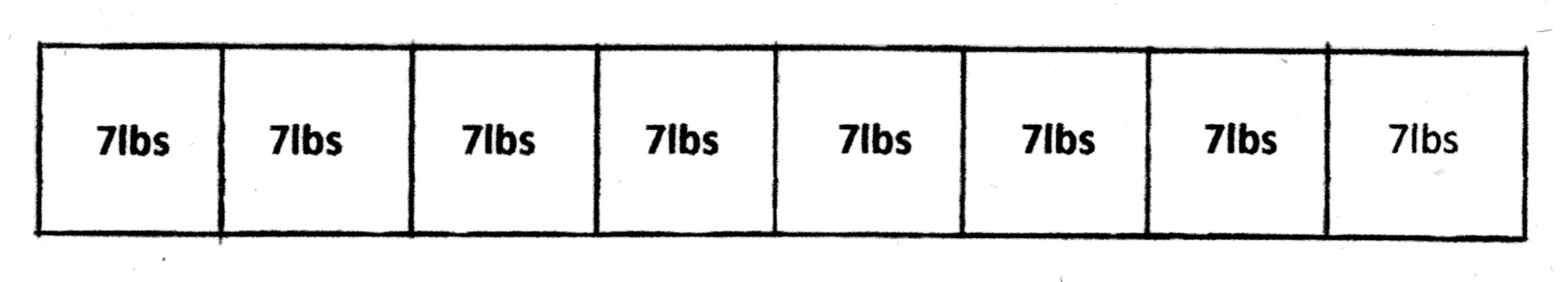

The air gets sucked out below the polythene sheet and air pressure will be exerted on the foam. Although the pressure can be as high as 14lbs per square inch at sea level, our methods may not be 100% efficient. There is less air pressure the higher we go. Let’s say we only achieve 7lbs per square inch – half the actual pressure. This is still mighty. An A4 piece of paper is about (200mm) (8ins) across. Cut a strip off the bottom about 25mm (1ins) wide. To keep the maths simple, that strip, if it was under the bag, laying on the table, would have 8 x 7lbs per square ins = 56lbs of pressure on it, with our very inefficient system. This approximates the weight of a sack of potatoes at 25kgms, or a bag of cement/sand. Such bags have been evolved as a comfortable, but heavy weight to be handled by an adult male and that pressure is being applied to the 200mm strip. Try to calculate the pressure on an 8ft x 4ft table. In fact, the paper as it is, would have 112lbs crushing on it, if a sea-level vacuum could be produced. Most importantly though, is the way the weight is applied. It is smoothly and evenly distributed, so that compressive distortions are avoided.

This approximates the weight of a sack of potatoes at 25kgms, or a bag of cement/sand. Such bags have been evolved as a comfortable, but heavy weight to be handled by an adult male and that pressure is being applied to the 200mm strip. Try to calculate the pressure on an 8ft x 4ft table. In fact, the paper as it is, would have 112lbs crushing on it, if a sea-level vacuum could be produced. Most importantly though, is the way the weight is applied. It is smoothly and evenly distributed, so that compressive distortions are avoided.

How is the pressure maintained?

Is the vacuum switched off? There can be several answers to this question, but the simplest answer for amateurs is – No, it continues to run. It works like this. The polyester resin is catalysed (has the setting-chemical added to it) to ‘gel’ within about 2 hours. This is normal good practice anyway. The cleaner can be organised to run gently, just to maintain the vacuum for that period of time, after which the air-tight seal can be released by switching off, because the critical bond between the foam and the glass will have formed. There will be more information about this later, but an important point to note is that the dirt collection system and filters inside the cleaner MUST be removed for this use, or the cleaner will overheat. They can be returned if/when it is used as a cleaner, which is quite frequently, throughout the project. Just remember to remove them for bagging.