GRP Flat-table Boatbuilding 3

What is foam sandwich and how does it work?

Limits

Boatbuilding in foam sandwich is a topic which touches on many other subjects in allied fields and it is difficult to discuss foam sandwich alone, without digressing into these other topics. In order to retain a focus on the specific subject and retain clarity of message, it may be necessary to avoid going too deeply into these other areas. This is particularly true of what might be called modern, ‘technical materials’ which are perhaps better dealt with elsewhere. We will return to these products periodically.

How does foam sandwich work?

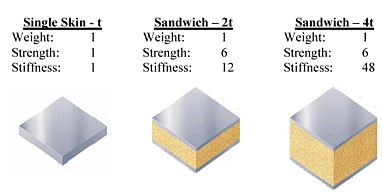

Simple really. It is about stiffness. Instead of having a sheet of solid glassfibre (GRP) four layers thick, which Right.Domestic door is very flexible, there are two layers of glass attached to either side of a layer of foam. They ‘sandwich’ the foam, hence the name foam sandwich. The effect of this is to make a very stiff structure from one that was previously flexible. Rigidity is the first quality which is gained. To understand why, one must understand a little about structures and see how the principle is used in other everyday situations.

Simple really. It is about stiffness. Instead of having a sheet of solid glassfibre (GRP) four layers thick, which Right.Domestic door is very flexible, there are two layers of glass attached to either side of a layer of foam. They ‘sandwich’ the foam, hence the name foam sandwich. The effect of this is to make a very stiff structure from one that was previously flexible. Rigidity is the first quality which is gained. To understand why, one must understand a little about structures and see how the principle is used in other everyday situations.

A simple illustration of the system working can be seen in ordinary domestic doors. The door might be 35mm thick, but its faces are just two thin skins of particle board (hardboard) about 5mm thick. They are held apart by strips of wood around the edges and a honeycomb of cardboard on the inside. The individual skins are flexible and the cardboard interior has little strength, but combined together they makes a stiff, lightweight structure. Another place where the  principle is used in a super-sophisticated way is in modern racing cars, but they do not use basic polyester resin and glass, instead they use the ‘technical materials’, mentioned above, for their strengthening strands and the resins.

principle is used in a super-sophisticated way is in modern racing cars, but they do not use basic polyester resin and glass, instead they use the ‘technical materials’, mentioned above, for their strengthening strands and the resins.

Stresses

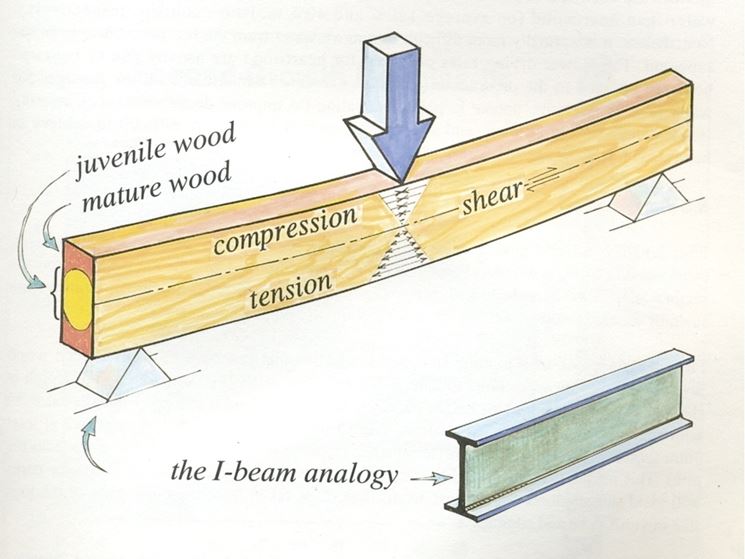

In engineering, the strength/stiffness is usually explained by reference to the ‘I’ beam, which can be quickly understood by reference to a diagram. A beam (possibly wood) bridges a gap to carry a load. It is pushed down in the middle. The bottom of the beam is  being stretched by this load, so the fibres are in tension. Along the top of the beam the fibres are being crushed together, so they are in compression. At some point midway across the beam, from top to bottom, the forces have to change from tension into compression, so the tension must gradually become less as it moves towards the centreline of the beam. The same applies to the compressive forces. About halfway across the beam, known as the axis, the opposing forces are no longer so strong.

being stretched by this load, so the fibres are in tension. Along the top of the beam the fibres are being crushed together, so they are in compression. At some point midway across the beam, from top to bottom, the forces have to change from tension into compression, so the tension must gradually become less as it moves towards the centreline of the beam. The same applies to the compressive forces. About halfway across the beam, known as the axis, the opposing forces are no longer so strong.

The next understanding can be illustrated by putting your hands together as if in prayer. Flex all the fingers to the left, then flex all the fingers to the right. In order to do this the opposing fingers must slide against each other. This sliding allows the movement. If the hands were permanently locked together, the movement could not happen. The single beam could be cut in half along its axis and the two cut halves separated. In a girder or ‘I’ beam, they can be held apart by a thin vertical strip called a shear web, whose job it is to stop the top and bottom flanges sliding against each other as the fingers did. The web does not have to be exceptionally strong and this is why some girders, Rolled Steel Joists (RSJ), can be seen with holes cut through them to make them lighter (see Chapter 2). Some roofing or scaffolding supports are made from lattice girders for the same reason. The combined or composite structure is now many times stiffer than before, with little additional material. This is how the foam in the sandwich works. It is the equivalent to the shear web holding the top and bottom flanges of the RSJ apart. The deeper the web (foam) the  greater the stiffness. Reminder

greater the stiffness. Reminder

I have already mentioned that I will try to keep references to glass and resin very simple, to help understanding. More complex materials will be explained later. Right. Additional stiffness values

Foam. There are many lightweight foams that can be used, providing the resin agrees with them. Polyester resin will dissolve polystyrene foam, so they cannot be used together. Vehicle chassis use aluminium skins and aapro-propylene foam - but to return to the real-world of amateurs – I used a PVC foam, whose trade name was Airex, in my constructions. Many commercial companies use balsa wood in boat construction, especially for decks. It is call end-grain balsa as the sheets are assembled with the grain standing vertically. The balsa could rot if water ever finds its way through the outer skin, which is almost inevitable with fixings. The PVC foam has closed-cell construction, so the internal bubbles do not connect. This meant that water cannot seep through it. It is fire retardant. Almost all commercially produced boats today will use sandwich construction in their build.

Glass. This is a big topic that can expand endlessly, so I will restrict myself, to try to keep it simple and describe some basic, relevant cloths. I have already mention Chopped Strand Mat (CSM) that has short fibres going in many different directions and is therefore limited in its ability to carry load. It has a diffusing effect on loads. I have heard boat builders say that there is no place anywhere in a modern craft for CSM and they are probably correct. But amongst other things, I find it very good for ‘sticking things together’, prior to possibly applying other stronger mats, so it has its uses and must not be discarded. It is roughly the equivalent of the straw in mud bricks, but if you want to build a skyscraper you need longer continuous strands. Modern boats should have bundles of strands that run the full length of the boat or wrap right across it from one gunwale to another. Long strands of glass are called Rovings and when woven together they form cloth known as Woven Rovings. If the primary fibres lay mainly in one direction held in place only by lighter fibres crossing them, they are then Unidirectional Woven Rovings (UDWR). Such cloth will be many times stronger than CSM.

Industrial weaving techniques have made it possible to produce Bi-axial, Tri-axial and even Quadraxial cloths which are immensely strong and yet require less work and less resin to achieve the same structural strength. Fibres such as Kevlar and Carbon are now used in addition to glass as they are many times stronger, but also many times more expensive. All these cloths are currently used in GRP constructions. The suppliers of all the products mentioned here are easy to find using the internet and I will name at least one later. They are expert in what they do and very willing to look at any project and advise about materials as well as publish ‘How to do it’ videos. It is not my intention to offer materials specifications, only to explain a simple method for the amateur to use to build, modify, or repair a boat. I stress, look at supplier's lists of materials to learn more. Choose suppliers reasonably close to you and when you are ready to start a project, talk to them, show them drawings and ask for their recommendations. They will help you.

Advantages of Foam Sandwich

There is a lot of work in the making of any boat, but using this method produces some special qualities.

- The weight of the structure is comparable with other material methods

- The structure is so strong that in small craft the size of pleasure boats, there is little necessity for intrusive extra internal stiffeners in the way of frames, ribs and stringers. The smooth interior space can be freed for accommodation.

- The structure is buoyant. Unballasted multihulls can be made unsinkable. Ballasted craft would require less reserve buoyancy to make them unsinkable. The boat is wearing its own lifejacket.

- There is a hull inside another hull with a shock absorbent, fire retardant, material between them. It is difficult to pierce the hull.

- The boat is insulated. It stays warmer longer when it’s cold and cooler during the heat of the day. In temperate climates this can effectively extend the sailing season. This quality is especially notable to sailors who have suffered condensation problem in boats made of alternative materials.

Whilst these articles concentrate of building with flat forms, it is quite possible to build with curved forms or to mix the two. This building method, as Kelsall said, can produce almost any shape (see below) including rounded shapes (see Chapter 10).

Left . Deck beam in front of cabin under construction (see picture right). Pictures. Paul Brown

Left . Deck beam in front of cabin under construction (see picture right). Pictures. Paul Brown

Note. Fast-curved, unglassed-foam, shaped in short sections being bonded to flatter, larger panels, made on flat table.

Chined hulls are perfect for foam-sandwich,

Plywood construction Below RM Yachts 1070

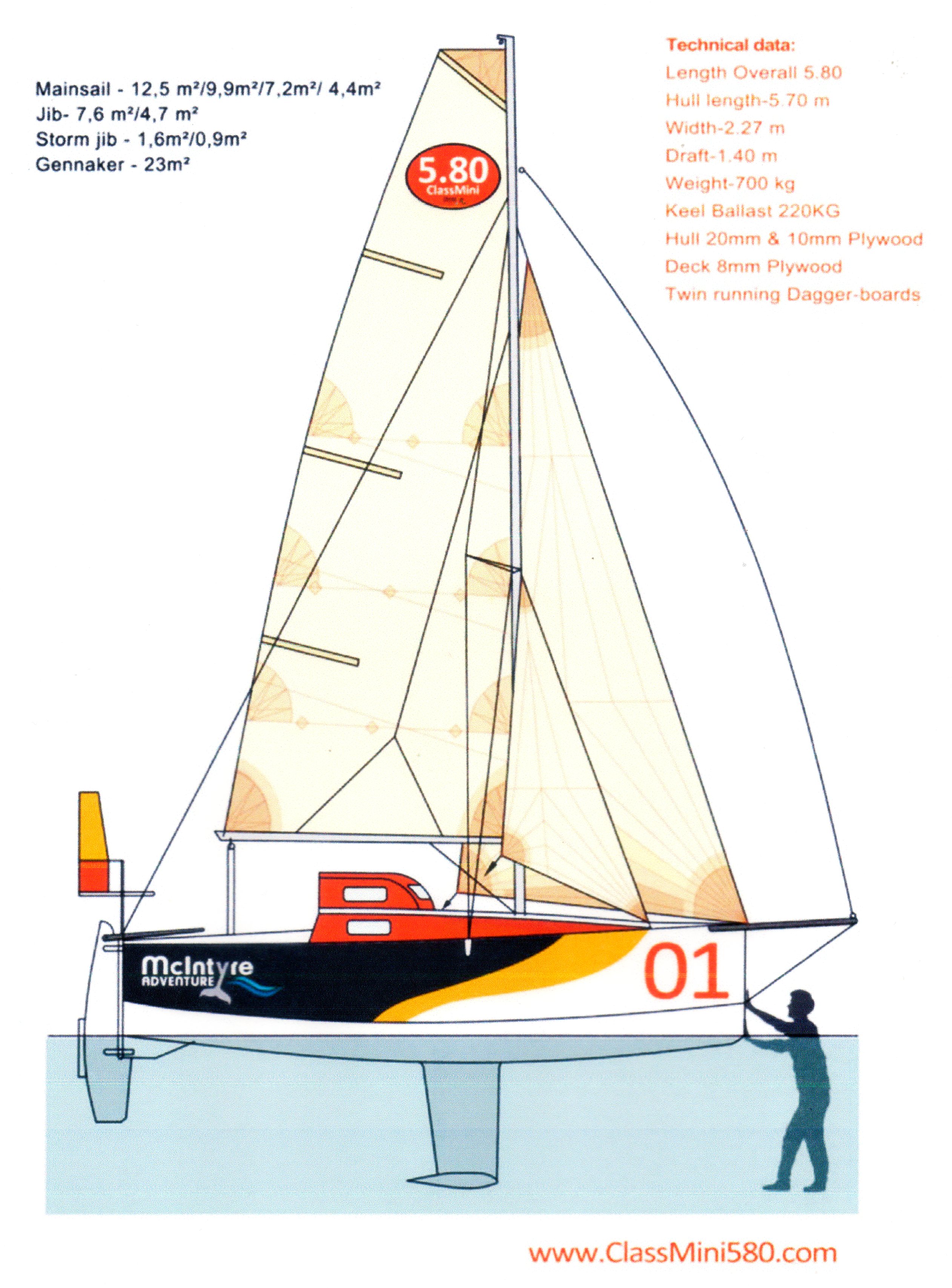

580 Class. Currently craft are being constructed to race in the 5.80 class (19ft). They are plywood designs and are being sold as plans and as a CNC-cut kit. They are skinned in glass cloth and filled to produce the smooth skin. They are a perfect example of craft that could be produced by the flat table method to avoid this lengthy surface treatment, internal stringers etc.

Their concept is excellent and it is strongly recommended that you access the websites and read about this craft and the ocean races organised for it.